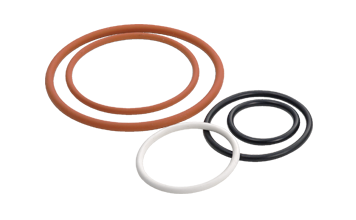

Nitrile (often referred to as Buna-N) is the most commonly used elastomer in the seal industry and is a copolymer of two monomers; acrylonitrile (ACN) and butadiene. The properties of this elastomer are ruled by the ACN content which is broken down into three classifications:

- High Nitrile: >45% ACN content

- Medium Nitrile: 30 – 45% ACN content

- Low Nitrile: <30% ACN content

The higher the ACN content, the better the elastomers resistance to hydrocarbon oils. With lower ACN content, the material offers better flexibility at low temperatures. Medium nitrile is, therefore, the most widely specified due to its good overall balance in most applications.

Typically, nitrile rubber can be compounded to work over a temperature range of -35°C to +120°C and is superior to most other elastomers in regard to compression set, tear and abrasion resistance.

Nitrile rubbers posses excellent resistance to oil-based fluids, vegetable oils, greases, water and air.